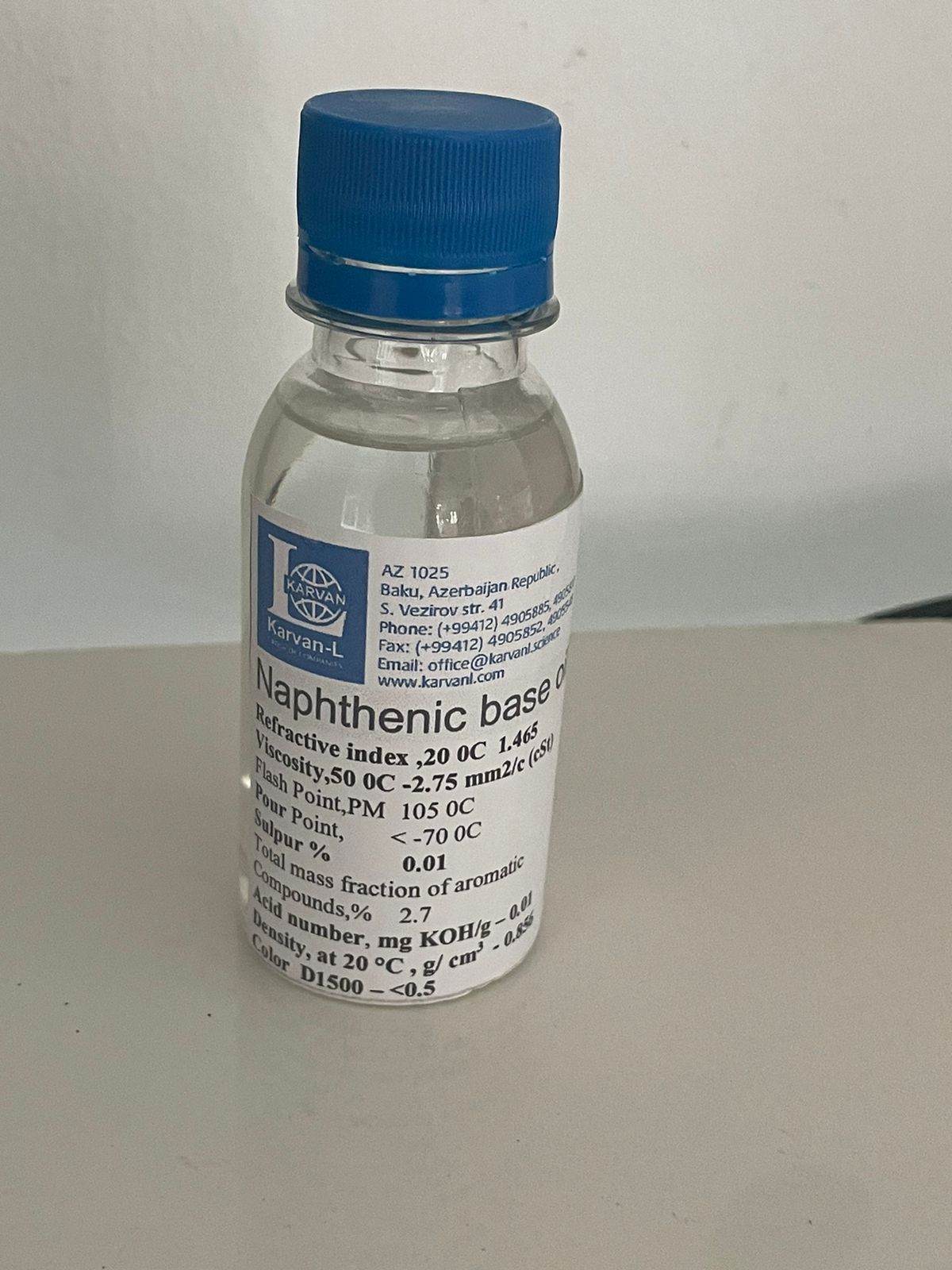

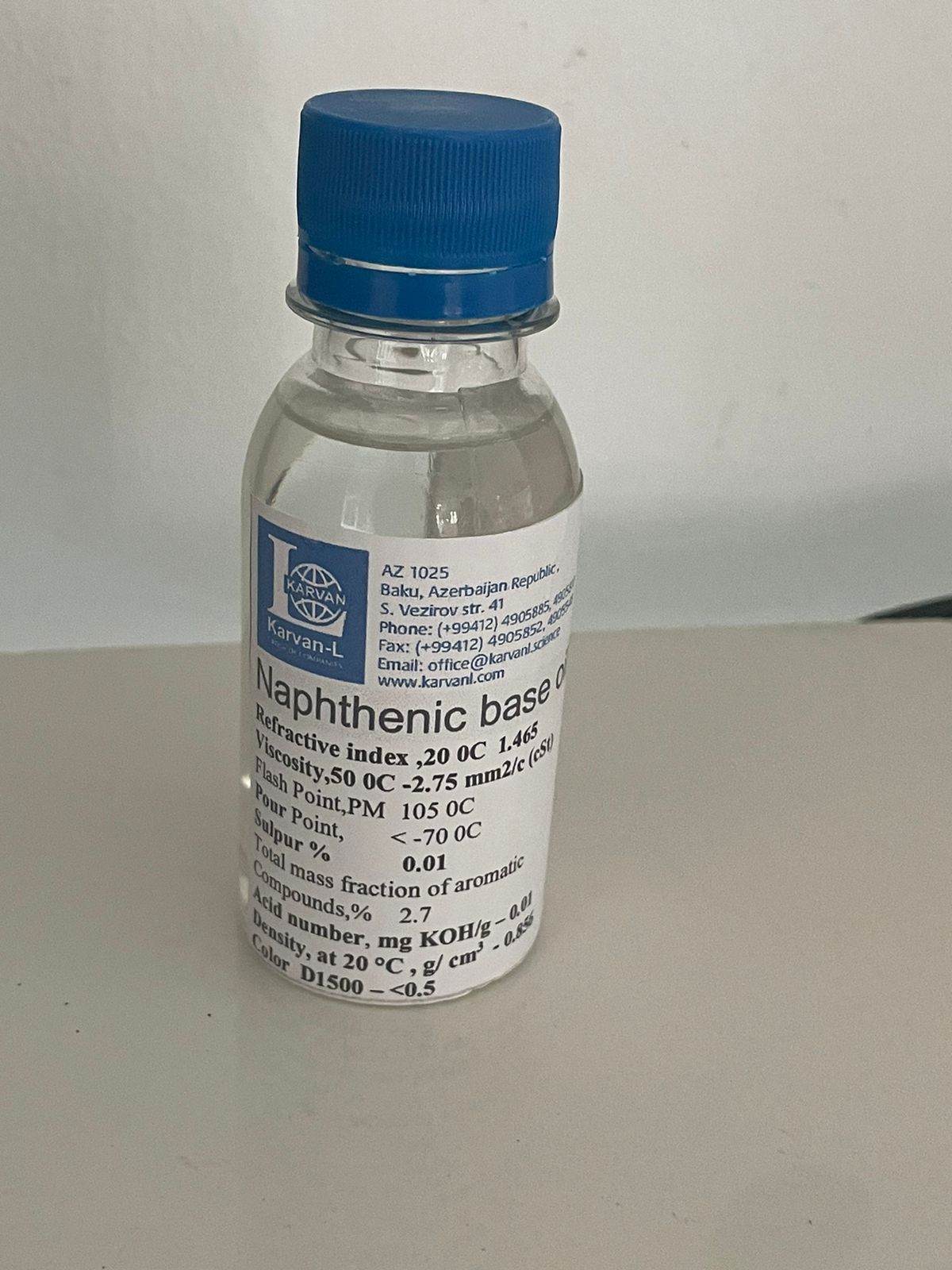

Naphthenic base oil

Naphthenic base oil applications

Naphthenic base oil is a kind of group V base oil that is produced by hydro-treating sweet crude distillates at pressures exceeding 2500 psi. Low pour point, excellent liquidity, low wax, and low aromatic content characterize naphthenic base oil. Furthermore, these oils have excellent low-temperature capabilities, which increases the lubricant compositions’ low-temperature qualities. Naphthenic base oils also function better at low temperatures than paraffinic oils, making them appropriate for hydraulic and automatic transmission fluid formulation. Because of their high solvency power, naphthenic oils respond well to antioxidants and additives. Also known as pale oil, naphthenic base oils contain much less wax than a comparable paraffinic base oil, which gives them much better low-temperature pour points in addition to higher solvency performance.

Naphthenic base oils for lubricating greases

1. The superior solvency power of naphthenic oils, bring advantages to grease production, such as lower soap consumption and cooking temperatures, which translates in lower energy consumption, costs, and ultimately lower environmental impact.

2. Greases produced with Naphthenic oils have superior low temperature properties and are pumpable at very low temperatures

3. Naphthenic based greases have superior low temperature properties than paraffinic based ones, something that becomes evident when looking at their pumpability, especially at temperatures between -10 and -30˚C.

Naphthenic base oils for metal cutting and removal fluids

1. The main function of cutting- or removal fluids (as they are also known), is that of cooling and lubricating the machined part and the cutting tool. Additionally, removal fluids wash away metal chips, and protect the workpiece and the machine from corrosion.

2. The superior solvency power of naphthenic oils helps them to dissolve high amounts of performance additives, and keep these in solution. The high solvency power brings advantages to the use of naphthenic base oils in the formulation of water-based fluids, as emulsion stability is improved.

3. The relatively high density and low viscosity index of naphthenic oils confers superior heat transfer properties, resulting in a more effective cooling of the different machine parts. The superior solvency powers of naphthenic oils help them to dissolve high amounts of performance additives, and keep these in solution.

Naphthenic base oils for metal forming fluids

1. The superior solvency power of naphthenic base oils help them to dissolve high amounts of performance additives, and keep these in solution. This high solvency power brings advantages to naphthenic base oils in the production of water-based fluid in terms of formulation flexibility.

2. The relatively high density and low viscosity index of naphthenic oils confers them superior heat transfer properties, resulting in a more effective cooling of the different machine parts. The superior solvency power of naphthenic oils help them to dissolve high amounts of performance additives, and keep these in solution. This high solvency power brings advantages to naphthenic oils in the production of water-based fluids, in terms of formulation flexibility, and once formulated, naphthenic based emulsions are known to be very stable. Here again the high density of naphthenic oils contributes to the stability of emulsions based on them in centralized lubricating systems, where these water-based formulations are less sensitive to the centrifugal forces of the pumps.

Naphthenic base oils for industrial lubricants

1. Naphthenic oils can be used as complementary fluids in the formulation of several industrial lubricants. Their high solvency power contributes not only to the dilution of additives in these formulations, but also once to dissolve deposits and debris once the lubricants are being used.

Naphthenic base oils for refrigeration fluids

1. The primary function of refrigeration oil is to lubricate moving parts in the compressor. Additionally, the oil act as a coolant, dampens noise and work as an electrical insulator. It is crucial that the oil is soluble in the refrigerant used and a low floc point would indicate a suitable combination. Correct viscosity of the oil is another important property to provide sufficient lubrication and at the same time function as a coolant.

| № | Physical characteristics | Naphthenic base oil (premium class) |

| 1 | Refractive index at 20 o C | 1.465 |

| 2 | Viscosity at 50 o C | 2,75мм2/c |

| 3 | Flash point | 105 0 C |

| 4 | Pour point | < -70 0 C |

| 5 | Sulphur | 0,01 |

| 6 | Total mass fraction of aromatic compounds (%) | 2,7 |

| 7 | Acid number mg KOH/g | 0,01 |

| 8 | Density at 20 o C g/cm3 | 0,856 |

| 9 | Color D1500 | < 0,5 |

| № | Physical characteristics | Naphthenic base oil |

| 1 | Refractive index at 20 o C | 1.4687 |

| 2 | Viscosity at 50 o C | 4,2 mm2/c |

| 3 | Flash point | 95 0 C |

| 4 | Pour point | < -72 0 C |

| 5 | Sulphur | 0,01 |

| 6 | Total mass fraction of aromatic compounds (%) | 10 |

| 7 | Acid number mg KOH/g | 0,012 |

| 8 | Density at 20 o C g/cm3 | 0,950 |

| 9 | Color D1500 | < 1,5 |